Automation of agrofood and industrial markets

Automation, mechanization,

Ultrasonic and robotics

Mastering automation since 1995, MatissEquipment, a division of Matiss, imagines, designs, manufactures, and integrates mechanical and robotics solutions for businesses automating their operations!

MatissEquipment has carved out a niche in the automation of manufacturing companies in many sectors as well as in the food industry.

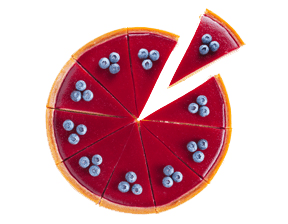

The automation of the food industry

Ultrasonic cutting and robotics solutions for the agrofood industry.

Automation solutions for the industrial sector.

Discover tailored mechanization and robotization solutions by MatissEquipment.

Discover MatissEquipment

Dedicated to automation and robotics solutions in the food and industrial industries, our mission is to make you more competitive in the manufacturing of your products.

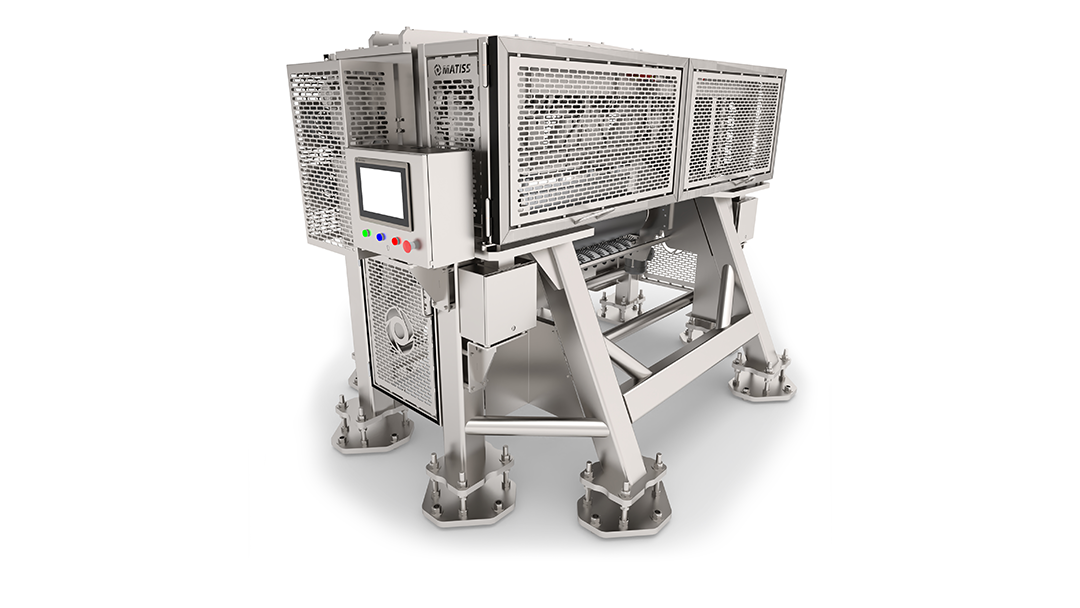

Ultrasonic cutting equipment

Ultrasonic blade cutting for a remarkable presentation of your products

If you have problems with your conventional cutting technique, such as food constantly sticking to the blade, low cutting speed, and a cut that is not as clean as you desired, you will definitely find a solution from the Matissonic product line. Whether it is for your pastries, granola bars, cheeses, deli meats, or prepared meals, your cut and size quality will be upgraded.